It’s been a tough road to build our first greenhouse at the Blind Center’s newly purchased 14 acre campus plot – we affectionately, and accurately call the Farm. Our Pamlico Rose Institute “PRI Health Corps,” a public health initiative partnership between the CDC and AmeriCorps, learned new skills and acquired knowledge and experienced opportunity along the 4-month journey. Building this greenhouse is also part of an overall program of building wellness gardens to mitigate food insecurity that puts this newfound learning to test. Oh yeah, we discovered a vein of resilience that ran through our crew.

We began our quest in early November selecting an appropriate site and leveling, and then grading the land on tractors and a bobcat we learned how to operate. We hand dug out a 48 inch wide, 4 inch deep 100-foot-long channel down the spine of the greenhouse floor, then added 14 tons of ABC rock mix for our wheelchair accessible walkway. We used hand augers to dig 3 foot holes, the last 2 feet through clay and then concreted 35 4 foot metal sleeves to hold the greenhouse skeleton. That in itself was something to write home about, however the most daunting action and activities beckoned off the ground, “and up.”

Working with the bones of a donated and used greenhouse, we methodically, and not without some frustration, pieced and bolted together parabola-shaped 16-foot-long aluminum poles. Testing our teamwork, we had to bend the poles over and across purloins we put up that extended the length of the greenhouse. Thirty-five times a team of six had to work to steady and like a pole vaulter, bend one end of the pole, bolting it in and then doing the same on the other side. This completed the frame. Two of the last tasks included running a 1×6 wood waist board on either side the length of the greenhouse for stability. To the waistboards, we screwed in a metal channel for the wiggle wire serving to grasp and hold in place the plastic roof. And finally, we framed in front and back doorways. We also built 15 3’x8’x 30” high growing and planting tables to get us started once we were ready to start.

And then…we waited.

The greenhouse sat on the ground looking like a large half-exposed fossil dinosaur, the parabolas of metal resembling giant ribs from high above or across the field from Rt 17.

It had taken us four months to get to this last stage of our journey. The description of our efforts makes it seem so straight forward. But it wasn’t. There were days after it rained, when moving around left us half sliding on clay turned to swamp. On other days, the clay was concrete-like, grudgingly yielding to shovels. The cold temperatures of January and February often were accompanied by winds that blew across the barren fields around us, scything through our layers of clothes and gloves. Then, layered on top of mother nature, were days when bent, rusted, or both, pieces of metal resisted efforts to conform to design that we gleaned from YouTube videos or intuition that wasn’t always right. Progress was measured not in what we did, but in how many steps back we took that undid what we had done.

Did I mention resilience? Each step back, we learned something we didn’t know. More than occasionally, we had to improvise, repurposing metal scraps on site or looking for answers in surplus materials offsite. Each roadblock was an opportunity to discover more about the structure, each problem became part of the solution for the next impasse. Vietnam Navy Veteran Herb directed his considerable array of mechanical skills to the task and Army Veteran Darnnell became his shadow. Susan applied resident knowledge of gardening, with information she was getting “real time” from her agribusiness courses to help us envision function and purpose critical to appreciate during construction. To the rest of the team, what we knew about greenhouses, or the skills required to build one, lay outside our life experience. But by the time the greenhouse was ready for the final step, members like Sean and Jess were adding perspective and nuance, as well as muscle to the effort. In a nutshell, that is resilience, overcoming adversity through community.

I dare to say, if our plucky PRI Health Corps built another greenhouse, it would go up in record time. I also know, from my own experience through this journey, that we all have learned skills and knowledge that may be useful in future endeavors not yet here or even imagined. That is also the mark of resilience. Programs like AmeriCorps and the Peace Corps are the children of FDR’s Civilian Conservation Corps. They may not compare with other employment opportunities in some things, but members leave their tenure providing services to those in need or at risk, at home, or internationally, across multiple sectors; education, economic development, youth and public health and graduating” with an applied degree in resilience, beneficial to whatever path they choose.

Our emperor greenhouse had no clothes. The last step was putting on a 140 ft by 40 ft plastic sheet requiring a strategic plan and well-oiled team effort.

In early March, windless days are infrequent, especially on the “prairie.” Anxiety hummed in the background as we bided our time. Visions of wind gusts turning our plastic into a giant kite with team members dragged along ending up the next county over as fantastical as they might seem, colored our expectations of what to expect.

And that is why we were waiting.

In the end, when late last week, a morning came without wind, it turned out not to be the calm before the storm we fretted over. We assembled right after sunrise, unraveled our plastic, and gathered and listened to Herb explain in his outside voice the plan, laced with affection-at we imagined it was that: bundle tennis balls in edges of the plastic periodically along the length. Tie ropes to the balls and toss them over the frames. On go, pull ropes, and plastic will creep up and over and down the other side. Someone like me is inside running up and down the middle of the greenhouse with a tennis ball on a broom stick like a drum major herding a kazoo band of 5 year olds to help keep the plastic from getting stuck and/or tangled on the top. Once over, pull tight and slide in the wiggle wire to securely attach the plastic. Job done.

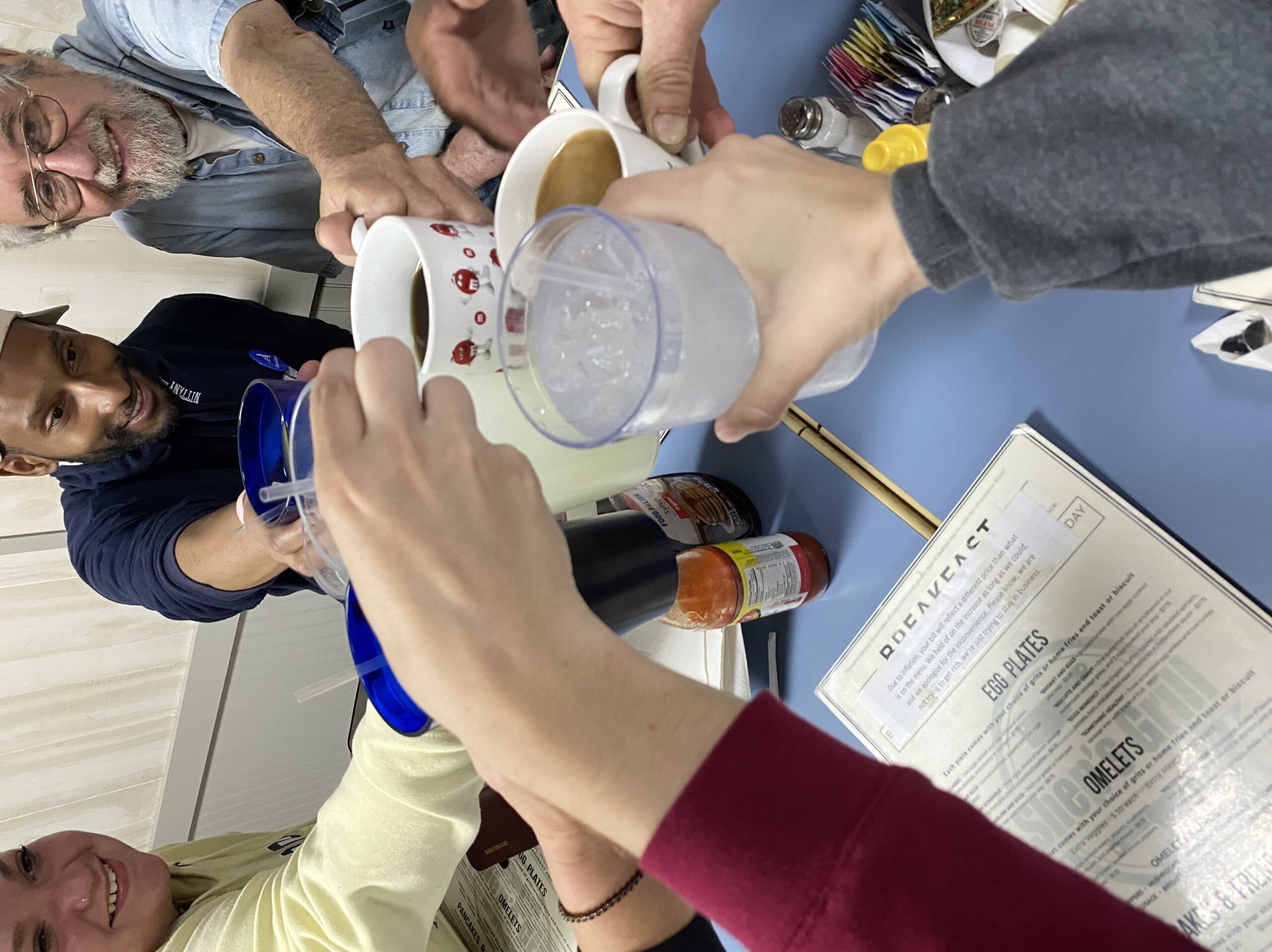

Four hours later, our team was sitting down at Shep’s Grill to a brunch celebrating the ease and success of Herb’s plan – plastic stretched taught. It turns out, after four months of building from the ground up, we had this cold. PRI Health Corps and the Blind Center now had a functioning greenhouse.